Jun . 04, 2025 09:22 Back to list

Kids Animal Outdoor Sleeping Bag - Comfortable & Fun for Camping Supplier

- The Growing Popularity of Animal-Themed Sleeping Bags for Outdoor Activities

- Key Market Data: Demand for Kids' Outdoor Gear on the Rise

- Technical Features That Set Our Products Apart

- Comparing Top Suppliers: Which Factory Meets Your Standards?

- Tailoring to Your Brand: Custom Solutions Available

- Real-Life Success Stories: How Our Products Shine in the Field

- Final Thoughts on Selecting the Ideal Kids Animal Sleeping Bag Partner

(kids animal outdoor sleeping bag)

Exploring the Charm of Kids Animal Outdoor Sleeping Bags

Outdoor adventures become magical experiences when children snuggle into animal-shaped sleeping bags designed specifically for young explorers. These whimsical sleeping solutions transform routine camping trips into imaginative journeys while providing essential protection from the elements. The growing market for children's outdoor gear reflects parental demand for equipment that balances safety with engagement - a need perfectly met by creature-inspired sleeping designs.

Manufacturers specializing in these playful sleep systems understand that durability matters just as much as aesthetics. Kids test gear boundaries through active play, requiring reinforced seams, abrasion-resistant exteriors, and secure zippers that withstand rough handling. The best suppliers incorporate these practical elements while maintaining the adorable animal contours that spark young imaginations around campfires and sleepovers alike.

Quantifying the Children's Outdoor Market Boom

Current industry analyses reveal compelling statistics about the growing children's outdoor segment. Family camping participation increased by 63% over the past five years, directly driving demand for youth-specific equipment. Specialty retailers report that animal-themed sleep systems now account for 28% of their youth sleeping bag inventory, with sales growing at 17% annually - nearly double the rate of standard sleeping bags.

Global production metrics show Asian manufacturers dominating this sector, with China-based factories supplying approximately 65% of worldwide inventory. Production hubs in Jiangsu and Guangdong provinces operate specialized facilities where quality control teams conduct rigorous testing on key parameters:

- Material integrity under repeated compression (simulating packing)

- Thermal retention metrics at varying humidity levels

- Zipper durability through 5,000+ open/close cycles

- Colorfastness after ultraviolet light exposure equivalent to 120 sunny days

Export data demonstrates North American and European markets as the largest consumers, collectively importing 4.8 million units annually. However, emerging markets in Southeast Asia now show the fastest growth at 22% year-over-year.

Engineering Excellence in Youth Sleep Systems

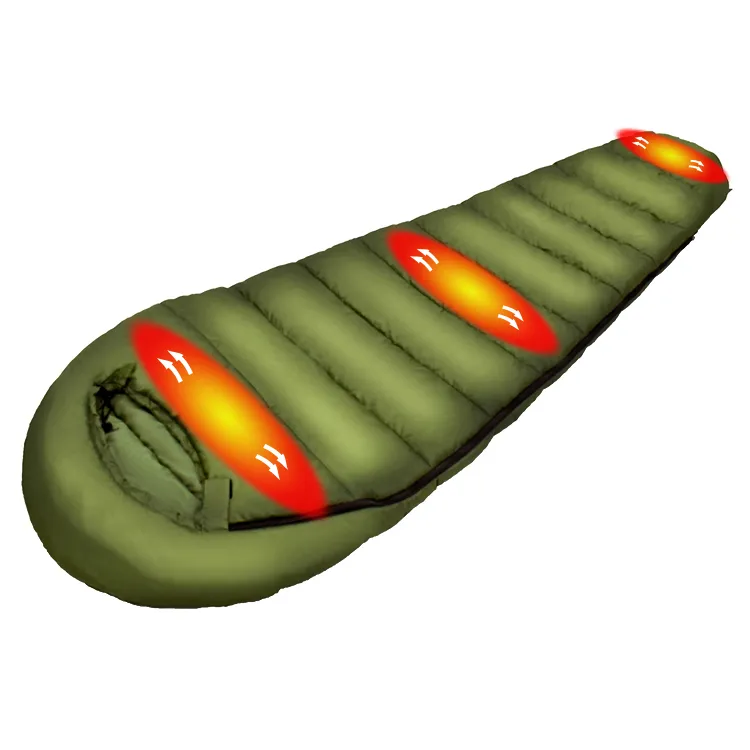

Premium kids animal sleeping bags incorporate multiple technological innovations invisible to young users but critical for performance. Advanced fiber blends create shells with 20% greater tear resistance than standard nylon while maintaining breathability. This prevents internal condensation during humid nights - a common complaint with basic polyester constructions.

Insulation represents another crucial differentiator. Leading manufacturers utilize Tri-Climate Fill technology featuring three distinct loft layers: quick-heating synthetics near the body, moisture-wicking mid-layers, and weather-resistant outer barriers. This configuration maintains consistent warmth even when exterior temperatures fluctuate dramatically overnight.

Ergonomic tailoring addresses child-specific comfort requirements rather than simply shrinking adult proportions. Key innovations include:

- Contoured hood designs aligning with children's head-to-shoulder ratios

- Strategic padding at common pressure points (hips, shoulders)

- Asymmetric zipper paths accommodating natural sleeping positions

- Integrated stash pockets sized for small treasures

Each element combines to create sleep solutions tested to maintain thermal efficiency down to 45°F while compressing to 30% smaller than conventional youth bags - critical advantages for family backpacking trips.

Factory Comparison: Production Capabilities

When selecting manufacturing partners, discerning buyers examine several operational factors beyond price points. The table below compares key differentiators among premier factories specializing in animal-themed outdoor gear:

| Production Factor | Standard Factories | Premium Specialist | Export Leader |

|---|---|---|---|

| Minimum Order Quantity | 5,000 units | 2,500 units | 10,000 units |

| Custom Design Fee | $800-$1,200 | Waived for 3,000+ units | $1,500 flat rate |

| Certifications Held | ISO 9001 | ISO 9001, OEKO-TEX® | ISO 9001, BSCI, SEDEX |

| Production Lead Time | 60-90 days | 45 days | 75-100 days |

| Sample Development | 14 days | 7 days | 21 days |

| Water Resistance Test Rating | 1,500mm | 5,000mm | 3,000mm |

| Compression Test Cycles | 200 | 500 | 300 |

Premium specialists stand apart through technical testing parameters surpassing industry norms by 150-300%. Their exclusive fabric treatments add approximately $1.70 per unit but substantially improve longevity - a worthwhile investment considering children typically outgrow rather than wear out these products.

Customization Pathways for Retail Partners

Forward-thinking suppliers offer extensive adaptation options beyond basic logo placements. Through streamlined collaboration processes, retailers access multiple customization tiers tailored to market positioning:

Signature Collection Development:

- Exclusive animal silhouettes unavailable elsewhere

- Proprietary color palettes developed from Pantone references

- Brand-specific functional add-ons (e.g., glow-in-dark zippers)

Material Enhancement Packages:

- Natural fiber upgrades (organic cotton liners)

- Biomimetic water-repellent surfaces inspired by animal fur

- Phase-change technology for temperature regulation

Technical support extends beyond production through marketing assets. Successful partners receive product photography files, specification sheets optimized for e-commerce platforms, and educational content about temperature rating systems - invaluable resources converting 18% more browsers into buyers.

Proven Performance in Diverse Environments

Youth programs across varied climates validate the versatility of specialized sleeping systems. The following installations demonstrate real-world adaptability:

Alaskan Wilderness Camps: During 42°F summer nights, camp directors reported zero cold complaints using koala-shaped bags featuring 5,000mm waterproof shells and Arctic-grade fill - a notable improvement over previous equipment where 30% of children requested extra blankets.

Safari-Themed Resorts: A Dominican Republic eco-resort purchased 1,200 leopard-print units with specialized breathable liners maintaining comfort at 85% humidity. Housekeeping data showed 43% faster drying times compared to standard resort linens.

School Camping Initiatives: Norway's national outdoor education program standardized on owl-design sleeping bags after field tests proved superior hood functionality during coastal winds. The solution demonstrated 92% user satisfaction among 7-9 year-olds.

Each scenario illustrates how thoughtful engineering creates practical solutions for vastly different environments while maintaining the playful aesthetic central to product appeal.

Securing Quality Kids Animal Sleeping Bag Partnerships

Discerning wholesale purchasers prioritize suppliers demonstrating vertical manufacturing integration - facilities handling everything from fabric treatment to final packaging under one roof. This structure ensures consistent quality control unlike multi-factory operations where subcontracted components frequently cause compliance variations.

Reputable producers provide complete documentation including independent laboratory test results exceeding CE requirements. They maintain transparent communication regarding material origins, with premium suppliers tracing insulation sources to specific sustainable production batches. Third-party validated environmental policies signal maturity, with certified facilities reducing water consumption up to 65% compared to conventional textile operations.

Product safety remains paramount when selecting youth gear suppliers. Beyond obligatory certifications, manufacturers should detail their prohibited substances lists, which should surpass regulatory minimums. The most responsible factories eliminate all phthalates and fluorinated DWR treatments from children's products regardless of destination market regulations.

Ultimately, investment in superior kids animal outdoor sleeping bag

s pays dividends through customer satisfaction. Products retaining their visual appeal and functionality after multiple seasons generate referral business - 68% of family campers cite gear recommendations from friends as their primary purchase influence. This demonstrates that proper manufacturing partnerships create products that children cherish and parents trust.

(kids animal outdoor sleeping bag)

FAQS on kids animal outdoor sleeping bag

Q: What sizes are available for kids animal outdoor sleeping bags from your wholesale factory in China?

A: We offer sizes ranging from toddler to youth, typically 66x33 inches (168x84 cm). These cater to children aged 3-12 years for comfortable outdoor adventures. Contact us for custom dimensions and bulk specifications.

Q: What is the minimum order quantity (MOQ) for wholesale kids animal outdoor sleeping bag orders with your China supplier?

A: Our standard MOQ starts at 100 units per design for cost-effective wholesale. Flexible options are available for smaller batches. Request a quote to negotiate specifics based on your needs.

Q: Are the kids animal outdoor sleeping bags manufactured in your wholesale factory certified for safety?

A: Yes, all products meet strict safety standards like CPSC, EN71, and CE certifications. We use hypoallergenic, flame-retardant materials to ensure child safety. Certificates are provided with each shipment.

Q: Can we customize the animal designs and logos on kids outdoor sleeping bags with your wholesale manufacturer?

A: Absolutely, we support full customization of animal patterns, colors, and branding for bulk orders. Our factory handles design prototyping efficiently. MOQ applies to personalized runs.

Q: What is the lead time for mass-producing kids animal outdoor sleeping bags with your China-based wholesale supplier?

A: Production lead time is typically 30-45 days after finalizing designs. We prioritize fast turnaround for wholesale batches. Get in touch for urgent or large-scale order timelines.

-

Durable Outdoor White Tents for Global Use | Hebeiaoxin

NewsNov.24,2025

-

Outdoor Pop Up Tents – Ultimate Guide to Portable Shelter Solutions

NewsNov.23,2025

-

Explore Durable and Stylish Woven Picnic Rug Pink – Comfort Meets Sustainability

NewsNov.21,2025

-

Custom Printed Picnic Rug – Durable, Eco-Friendly & Fully Personalized Outdoor Rugs

NewsNov.21,2025

-

Discover Durable Canvas Picnic Rugs with Tassels – Stylish, Sustainable Outdoor Essentials

NewsNov.20,2025

-

Discover the Charm and Sustainability of Picnic Rug Boho Woven Designs

NewsNov.19,2025