Nov . 04, 2024 13:50 Back to list

Top Manufacturers of Premium Galvanized Wire Mesh for Industrial Use

The Importance of High-Quality Galvanized Wire Mesh Factories

In today's industrial landscape, the significance of high-quality galvanized wire mesh cannot be overstated. This versatile material serves a plethora of applications ranging from construction and agriculture to security and filtration. When it comes to producing top-notch galvanized wire mesh, the role of factories specializing in this area is paramount. This article explores why high-quality galvanized wire mesh factories are critical, the processes they employ, and the benefits of choosing quality products.

What is Galvanized Wire Mesh?

Galvanized wire mesh is made from steel wire that has been galvanized, which involves coating it with zinc to prevent corrosion. This treatment not only enhances the wire's durability and longevity but also improves its performance in various environments. Galvanized wire mesh is commonly used in fencing, concrete reinforcement, animal enclosures, and as a protective barrier. Its strength and resilience make it an essential material across numerous industries.

The Role of Factories in Production

High-quality galvanized wire mesh factories implement rigorous manufacturing processes to ensure that their products meet stringent industry standards. These factories typically employ skilled workers and utilize advanced machinery, including automated wire weaving systems and galvanizing baths. The combination of expertise and technology allows them to produce mesh that is not only durable but also consistent in quality.

The galvanization process itself is critical. Factories that utilize hot-dip galvanization typically provide superior protection against rust compared to those using electro-galvanization. The former process immerses the wire in molten zinc, creating a thicker coating that can endure harsher environmental conditions. High-quality factories prioritize this method to ensure their products are long-lasting.

Quality Control Measures

high quality galvanized wire mesh factories

Quality control is a cornerstone of any reputable galvanized wire mesh factory. These facilities often have stringent testing protocols in place. This includes testing the wire's tensile strength, corrosion resistance, and mesh size accuracy. By maintaining high standards in quality control, factories can guarantee that their products will perform under various conditions and meet the expectations of their customers.

The Benefits of Choosing High-Quality Products

Opting for galvanized wire mesh from a reputable factory comes with numerous benefits. First and foremost is the enhanced durability; high-quality products are less likely to corrode, ensuring that customers receive a long-lasting solution. This translates into cost savings over time as customers spend less on replacements and repairs.

Additionally, high-quality wire mesh ensures better performance in applications such as construction and agriculture. For instance, in construction, using strong and reliable mesh for concrete reinforcement can enhance the structural integrity of buildings. In agriculture, durable fencing can safeguard crops and livestock, minimizing losses.

Furthermore, purchasing from a factory that emphasizes quality often guarantees better customer support and service. Reputable manufacturers are more likely to offer warranties and assistance, ensuring customers have recourse should issues arise.

Conclusion

In conclusion, the production of high-quality galvanized wire mesh is critical to a multitude of industries. Choosing a reliable factory that implements rigorous quality control measures and utilizes advanced manufacturing techniques ensures that the galvanized wire mesh will perform adequately under various conditions. This not only provides customers with peace of mind but also contributes to the overall success of their projects. As industries continue to evolve, the demand for quality galvanized wire mesh will undoubtedly grow, making the role of specialized factories even more vital in the future.

-

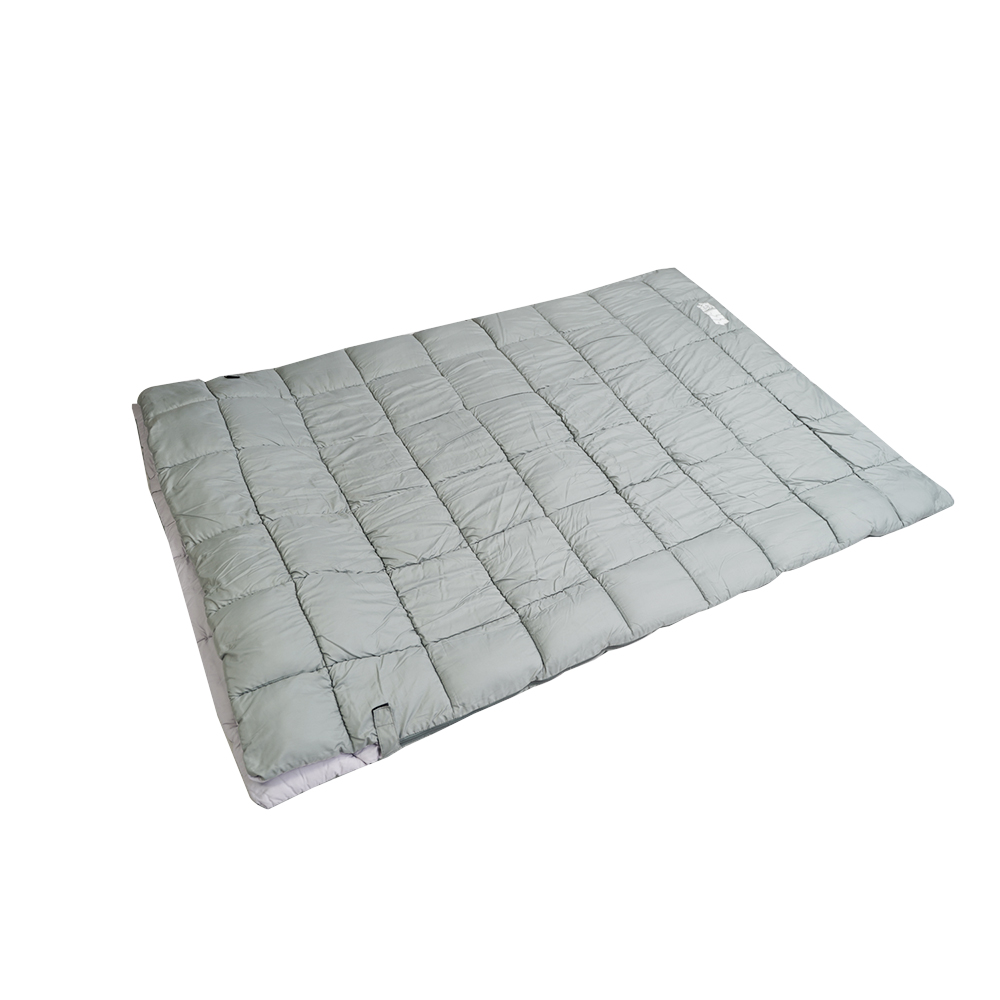

Picnic Blanket Backpack – Durable Quilted Mat, Ideal for Outdoor Activities, Direct from Factory

NewsJul.08,2025

-

Picnic Blanket Fleece – Extra Large, Soft & Durable Outdoor Blanket from Leading Factory Suppliers

NewsJul.08,2025

-

Premium Outdoor Sleeping Bag for Baby – Wholesale Suppliers, Factories & Manufacturers

NewsJul.08,2025

-

Sleeping Bag Camping Wholesale – China Outdoor Camping Sleeping Bag Manufacturer & Supplier

NewsJul.07,2025

-

Best Outdoor Camping Tents for Sale China Wholesale Supplier & Manufacturer

NewsJul.07,2025

-

Waterproof Picnic Mat - Sand Free Beach Mat Blanket Factory & Supplier Direct Price

NewsJul.06,2025