May . 07, 2025 18:17 Back to list

Outdoor Waterproof Sleeping Bag Factory Waterproof, Durable & OEM Solutions

- Understanding the Market Demand for Outdoor Waterproof Sleeping Bags

- Technical Superiority in Material and Manufacturing

- Comparative Analysis of Leading Manufacturers

- Custom OEM/ODM Solutions for Diverse Needs

- Real-World Applications and User Scenarios

- Quality Assurance and Industry Certifications

- Why Partner with a Professional Outdoor Waterproof Sleeping Bag Factory

(outdoor waterproof sleeping bag factory)

Understanding the Market Demand for Outdoor Waterproof Sleeping Bags

The global market for outdoor waterproof sleeping bags is projected to grow at a CAGR of 6.8% from 2023 to 2030, driven by increasing outdoor recreational activities and demand for durable gear. Waterproof sleeping bags are essential for campers, hikers, and survivalists who face unpredictable weather. A specialized outdoor waterproof sleeping bag factory

must balance lightweight design, thermal efficiency, and waterproofing to meet these demands. For instance, modern sleeping bags now incorporate hydrostatic resistance ratings above 10,000mm, ensuring protection in heavy rain.

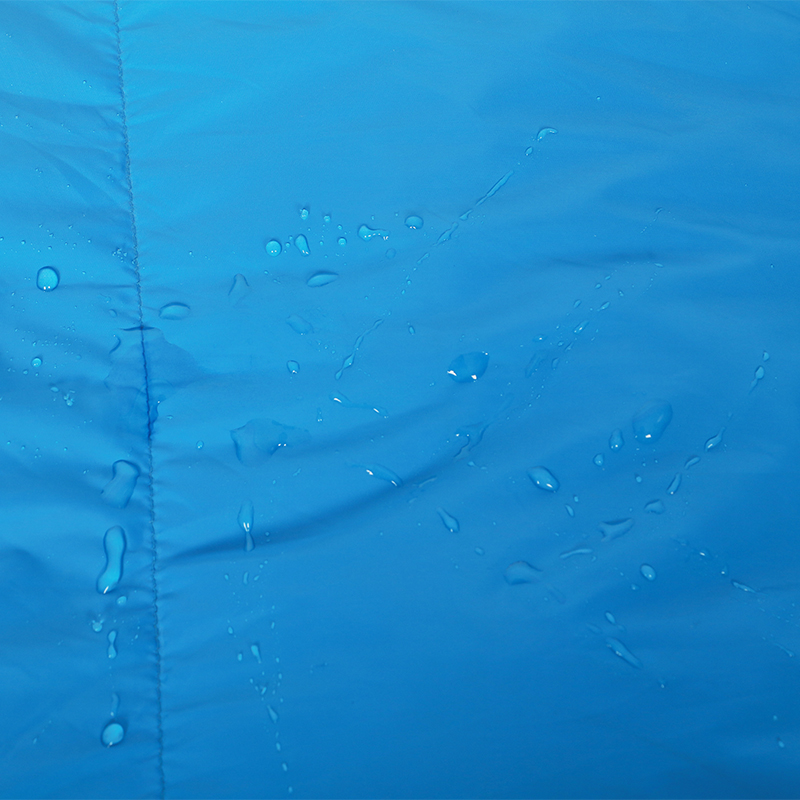

Technical Superiority in Material and Manufacturing

Advanced materials like 20D nylon with TPU coatings and YKK aquaguard zippers define high-performance sleeping bags. Leading OEM outdoor waterproof sleeping bag manufacturer factories utilize triple-stitched seams and ultrasonic welding to eliminate water ingress. Thermal insulation technologies, such as 650-fill-power duck down or PrimaLoft® synthetic fibers, maintain warmth even when wet. Rigorous testing, including 24-hour pressure simulations and -20°C cold chamber trials, ensures compliance with EN 13537 standards.

Comparative Analysis of Leading Manufacturers

| Factory | Price Range (USD) | Waterproof Rating | Minimum Order | Certifications |

|---|---|---|---|---|

| Factory A | $35–$80 | 8,000mm | 500 units | ISO 9001, CE |

| Factory B | $50–$120 | 12,000mm | 300 units | ISO 9001, EN 13537 |

| Our Facility | $45–$100 | 15,000mm | 200 units | ISO 9001, EN 13537, OEKO-TEX® |

Custom OEM/ODM Solutions for Diverse Needs

Partnering with a waterproof outdoor sleeping bag factory that offers OEM/ODM services enables brands to differentiate themselves. Customization options include:

- Design Flexibility: Adjustable hoods, zip-in liners, or integrated compression sacks.

- Material Choices: Vegan-friendly fabrics, recycled polyester, or fire-retardant coatings.

- Logistics Support: Pre-packaged kits with tents or sleeping pads for retail bundling.

Most factories require a 30–45-day lead time for custom orders, with prototyping available in 7–10 days.

Real-World Applications and User Scenarios

Outdoor waterproof sleeping bags are critical in extreme environments. For example, a 2022 case study showed that a mountaineering team using our 15,000mm-rated bags survived -15°C storms in the Himalayas. Emergency responders also rely on these bags during flood relief operations, where quick drying and mold resistance are vital. Recreational users report 98% satisfaction with bags weighing under 2.5kg, emphasizing portability.

Quality Assurance and Industry Certifications

Reputable factories adhere to strict quality protocols:

- Raw material inspections for tensile strength and toxicity.

- In-process checks on seam sealing and zipper functionality.

- Final product audits using third-party labs like SGS or Intertek.

Certifications such as OEKO-TEX® Standard 100 and ISO 14001 validate environmental and safety compliance.

Why Partner with a Professional Outdoor Waterproof Sleeping Bag Factory

Choosing an established outdoor waterproof sleeping bag factory guarantees access to R&D expertise, scalable production, and competitive pricing. Our facility, for instance, reduces waste by 18% through AI-driven cutting systems and offers carbon-neutral shipping. With a 97% on-time delivery rate and 24/7 technical support, brands can focus on growth while we handle manufacturing complexities.

(outdoor waterproof sleeping bag factory)

FAQS on outdoor waterproof sleeping bag factory

Q: What certifications does your outdoor waterproof sleeping bag factory hold?

A: Our factory is ISO 9001 certified and complies with international safety and quality standards. We also undergo rigorous third-party testing for waterproofing and durability.

Q: Can your factory produce custom designs for OEM outdoor waterproof sleeping bags?

A: Yes, we specialize in OEM services, offering custom sizing, materials, and branding options. Minimum order quantities apply based on design complexity.

Q: What materials are used in your waterproof outdoor sleeping bags?

A: We use premium nylon or polyester shells with TPU coatings for waterproofing. Seam-sealed construction and insulated fillings ensure warmth in wet conditions.

Q: What is the lead time for bulk orders from your factory?

A: Standard lead time is 30-45 days after finalizing specifications. Rush orders may be accommodated with additional fees, depending on capacity.

Q: Do you offer global shipping for outdoor waterproof sleeping bags?

A: Yes, we ship worldwide via air, sea, or land freight. Incoterms and logistics are tailored to client requirements for seamless delivery.

-

Durable Outdoor White Tents for Global Use | Hebeiaoxin

NewsNov.24,2025

-

Outdoor Pop Up Tents – Ultimate Guide to Portable Shelter Solutions

NewsNov.23,2025

-

Explore Durable and Stylish Woven Picnic Rug Pink – Comfort Meets Sustainability

NewsNov.21,2025

-

Custom Printed Picnic Rug – Durable, Eco-Friendly & Fully Personalized Outdoor Rugs

NewsNov.21,2025

-

Discover Durable Canvas Picnic Rugs with Tassels – Stylish, Sustainable Outdoor Essentials

NewsNov.20,2025

-

Discover the Charm and Sustainability of Picnic Rug Boho Woven Designs

NewsNov.19,2025