Sep . 12, 2025 07:20 Back to list

Best Waterproof Picnic Mat: Large, Durable & Portable

Industry Trends in Advanced Waterproof Outdoor Textiles

The demand for high-performance outdoor textiles is consistently surging, driven by increased participation in outdoor activities and the critical need for reliable equipment across various sectors, from recreational to military applications. Central to this evolution is the development of robust, durable, and highly functional materials. In this dynamic landscape, the quest for the best waterproof picnic mat represents a microcosm of broader industry trends emphasizing superior material science, advanced manufacturing, and user-centric design. Modern consumers and B2B clients alike seek products that offer not just basic utility, but also exceptional longevity, ease of maintenance, and adaptability to diverse environmental conditions.

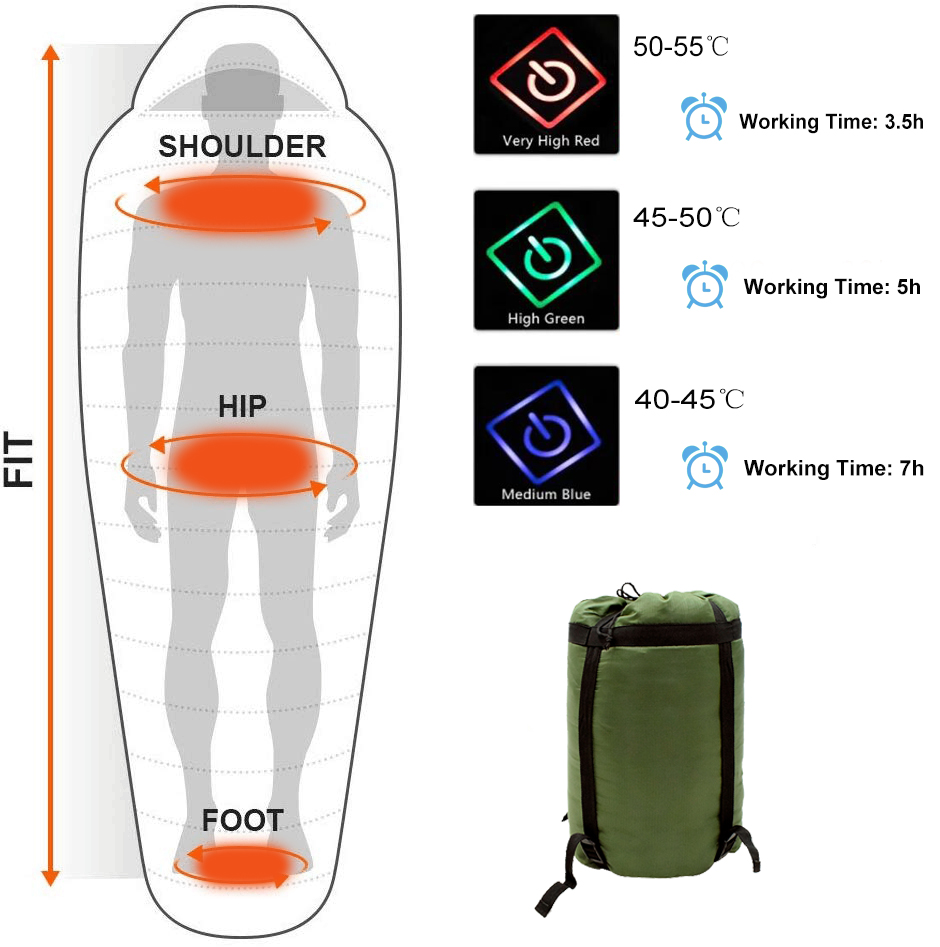

Key trends include the integration of sustainable materials, enhanced thermal regulation properties, and multi-functional designs that extend product utility. For instance, a large waterproof picnic mat is no longer just a ground cover; it's often designed to be easily packable, resistant to extreme temperatures, and provide a comfortable, dry barrier against diverse terrains. This evolution requires sophisticated material engineering, borrowing extensively from technologies developed for more demanding applications, such as military-grade sleeping bags or specialized protective gear. The market for outdoor picnic mat waterproof solutions is expanding rapidly, mirroring the broader growth in durable outdoor gear that withstands rigorous use and environmental challenges.

Technical Specifications and Material Science

Achieving the qualities of the best waterproof picnic mat demands a precise combination of advanced materials and meticulous engineering. The foundation typically involves high-denier fabrics such as ripstop nylon or polyester, chosen for their exceptional tensile strength and resistance to tearing. These fabrics are then augmented with sophisticated waterproofing layers.

Core Materials and Coatings:

- Face Fabric: Typically 70D-210D Ripstop Nylon or Polyester, offering a balance of lightweight properties and high abrasion resistance. For military-grade applications or an XL waterproof picnic rug, denier counts can exceed 400D.

- Waterproof Layer: Polyurethane (PU) coating, Thermoplastic Polyurethane (TPU) lamination, or Polyvinyl Chloride (PVC) backing. TPU is often favored for its flexibility, durability, and eco-friendliness compared to PVC, while PU provides a cost-effective solution with good performance. Hydrostatic head ratings commonly range from 3,000mm to 10,000mm, indicating robust water resistance under pressure.

- Thermal Insulation (Optional but valuable): For comprehensive ground insulation, particularly in cooler conditions, a thin layer of closed-cell foam (e.g., IXPE foam) or an aluminum foil backing can be integrated. This enhances comfort and helps conserve body heat, critical for a waterproof picnic mat large enough for prolonged use.

Key Performance Parameters:

- Hydrostatic Head (HH): Measures water resistance, expressed in millimeters. A higher HH value indicates superior waterproofing. For reliable outdoor use, an HH of 3000mm is a minimum, with premium products reaching 8000mm+.

- Abrasion Resistance: Evaluated using methods like the Martindale test, indicating the material's ability to withstand wear and tear. Essential for longevity when used on rough surfaces.

- Tear Strength: Measured in Newtons, quantifying the force required to propagate a tear in the fabric. Ripstop weaves inherently enhance this property.

- UV Resistance: Critical for outdoor products to prevent material degradation and color fading from prolonged sun exposure. Achieved through specialized polymer additives.

- Temperature Range: The operational temperature spectrum without material degradation or loss of flexibility, vital for materials used in cold weather or fluctuating climates.

Figure 1: Advanced composite material layers for superior outdoor protection.

Comparative Table: Waterproof Material Properties

| Property | PU Coated Polyester | TPU Laminated Nylon | PVC Backed Fabric |

|---|---|---|---|

| Hydrostatic Head (HH) | 3,000 - 6,000 mm | 5,000 - 10,000+ mm | 1,500 - 5,000 mm |

| Abrasion Resistance | Good | Excellent | Fair to Good |

| Flexibility in Cold | Moderate | Excellent | Poor (Stiffens) |

| Weight | Light | Light to Moderate | Heavy |

| Environmental Impact | Moderate | Low (often recyclable) | High (phthalates concern) |

Data based on common industry material specifications for outdoor textiles.

Manufacturing Process Flow for High-Performance Waterproof Mats

The production of a durable, high-quality waterproof picnic rug involves a sophisticated multi-stage manufacturing process, ensuring material integrity and optimal performance under diverse conditions. This systematic approach, leveraging advanced machinery and rigorous quality control, is crucial for delivering the best waterproof picnic mat to B2B clients.

Process Steps:

- Material Procurement & Inspection: Sourcing of high-grade ripstop nylon/polyester and advanced waterproofing laminates (TPU/PU). Incoming materials undergo stringent quality checks against ISO 9001 standards for denier, weave density, and initial coating integrity.

- Fabric Preparation & Weaving/Knitting: Raw fibers are precisely woven or knitted into base fabrics. For enhanced durability, a ripstop pattern is often incorporated during this stage to prevent tears from spreading.

- Waterproofing Treatment (Lamination/Coating):

- Coating: For PU-coated fabrics, the liquid polymer is precisely applied in multiple layers onto one side of the base fabric, then cured.

- Lamination: For TPU-laminated fabrics, a pre-formed TPU film is bonded to the base fabric using heat and pressure, creating an impermeable barrier without compromising fabric flexibility.

- Cutting & Shaping: Large rolls of waterproof fabric are precisely cut into desired shapes and sizes using automated CNC cutting machines. This ensures consistency and minimizes material waste, particularly for large picnic rug waterproof dimensions or custom designs.

- Assembly & Edge Finishing: Individual panels are assembled using advanced techniques.

- Welding: For highly waterproof and durable seams (e.g., using TPU or PVC materials), high-frequency welding or hot-air welding is employed to create a seamless, impenetrable bond.

- Stitching: For other materials, industrial sewing machines with specialized waterproof threads and seam-taping are used to ensure water integrity. All seams are taped with a waterproof film.

- Integration of Features: Attachment of carrying handles, storage pockets (e.g., for a picnic mat bag configuration), buckles, or additional insulation layers as per design specifications.

- Quality Control & Testing: Each finished product undergoes comprehensive testing, including:

- Waterproofness Test: Hydrostatic head testing on finished product samples.

- Seam Integrity Test: Pressure testing on welded/taped seams.

- Durability Assessment: Random abrasion and tear resistance tests.

- Dimensional Accuracy: Verification of size and weight against specifications.

- Packaging & Logistics: Products are cleaned, folded, compressed (if necessary), and packaged according to client requirements, often including vacuum sealing for compactness and protection during transit.

Figure 2: Precision cutting of waterproof textile components.

This controlled environment and adherence to robust testing standards ensure a service life typically ranging from 5 to 10 years, even under heavy usage, significantly outperforming conventional alternatives. Target industries for such high-grade waterproof textiles span petrochemical, metallurgy, water supply & drainage (for temporary covers), construction, and military/outdoor equipment sectors.

Application Scenarios and Technical Advantages

The versatility of a well-engineered best waterproof picnic mat extends far beyond casual outdoor meals, making it an indispensable asset for various B2B applications. Its robust technical advantages translate into tangible benefits across diverse operational environments.

Typical Application Scenarios:

- Outdoor Events & Festivals: Providing dry, comfortable seating areas for attendees, often involving large picnic rug waterproof designs for widespread coverage.

- Camping & Backpacking: Serving as a ground sheet for tents, a protective layer for gear, or an emergency shelter, leveraging its durable and waterproof picnic mat properties.

- Beach & Waterside Activities: Offering a sand-free and moisture-proof surface, ideal for family outings or commercial rental services.

- Sports & Recreation: Used as sideline seating for teams, protective covers for equipment, or an outdoor picnic mat waterproof base for yoga or exercise.

- Industrial & Construction Sites: Temporary ground covers for tools, materials, or personnel rest areas, where an XL waterproof picnic rug offers expansive protection.

- Emergency & Disaster Relief: Deployable as quick-setup ground insulation, basic shelters, or clean zones.

Technical Advantages:

- Exceptional Water and Moisture Resistance: With hydrostatic head ratings up to 10,000mm, these mats provide an impenetrable barrier against damp ground, dew, spills, and light rain, ensuring comfort and protection. This is a core advantage of any waterproof picnic rug.

- Superior Durability & Abrasion Resistance: Constructed from high-denier, ripstop fabrics and reinforced coatings, these mats withstand punctures, tears, and abrasive surfaces, significantly extending service life in demanding environments.

- Thermal Insulation Properties: Integrated insulation layers or material properties help to isolate users from cold ground temperatures, contributing to energy saving by reducing heat loss from the body, especially in colder climates.

- Corrosion and Mildew Resistance: Advanced coatings and material treatments render the mats resistant to mold, mildew, and bacterial growth, crucial for hygiene and longevity, particularly in damp conditions.

- Ease of Cleaning and Maintenance: Non-absorbent, smooth surfaces allow for quick wipe-downs or hose-offs, making maintenance effortless and preserving hygienic standards.

- Portability and Compact Storage: Despite their robust construction, intelligent design allows these mats to be folded or rolled into a compact form, often integrated with a picnic mat bag for convenient transport and storage.

- UV and Fade Resistance: Specialized polymer additives protect against degradation from prolonged sun exposure, maintaining material integrity and aesthetic appeal over time.

Figure 3: Demonstrating the resilience and waterproofing in outdoor settings.

Vendor Comparison for High-Performance Outdoor Textiles

Selecting the right manufacturing partner for your B2B waterproof textile needs, whether it's for the best waterproof picnic mat or other specialized gear, requires a thorough evaluation of vendor capabilities. Distinguishing factors go beyond mere price, focusing on long-term value, reliability, and innovative capacity.

Key Evaluation Criteria for B2B Vendors:

- Material Expertise and Sourcing: Top-tier vendors possess deep knowledge of advanced polymers, weaving techniques, and sustainable sourcing. They can advise on the optimal material combination for specific applications (e.g., lightweight versus extreme durability for a large waterproof picnic mat).

- Manufacturing Precision and Technology: Access to state-of-the-art machinery (CNC cutters, automated laminators, welding equipment) is paramount for consistent quality, tight tolerances, and efficient mass production.

- Quality Control and Certifications: Adherence to international standards (e.g., ISO 9001, Oeko-Tex Standard 100, REACH compliance) and robust internal QC protocols are non-negotiable for reliable product performance.

- R&D and Customization Capabilities: The ability to innovate and offer bespoke solutions – from specific dimensions (XL waterproof picnic rug) to integrated features (picnic mat bag design), specialized coatings (anti-fungal, fire retardant), and branding options – is a significant differentiator.

- Production Capacity and Lead Times: A reliable vendor can scale production to meet large orders while maintaining realistic and consistent lead times, supported by efficient supply chain management.

- After-Sales Support & Warranty: Comprehensive warranty commitments and responsive customer support reflect a vendor's confidence in their product quality and commitment to client satisfaction.

Vendor Comparison Matrix (Illustrative):

| Feature/Criterion | Premium Manufacturer (e.g., Aoxin's capabilities) | Mid-Tier Manufacturer | Budget Manufacturer |

|---|---|---|---|

| Material Quality (HH) | TPU/Nylon (5,000-10,000mm+) | PU/Polyester (3,000-5,000mm) | PE/PVC (1,500-3,000mm) |

| Customization | Extensive (materials, size, features, branding) | Moderate (size, basic branding) | Limited (standard sizes/colors) |

| Certifications | ISO 9001, Oeko-Tex, REACH, Military Specs | ISO 9001 | Basic QC |

| Seam Construction | Welded/Taped (seamless waterproof) | Stitched & Taped | Basic Stitching |

| Typical Lead Time | 4-8 weeks (for custom orders) | 6-12 weeks | 8-16 weeks |

| Product Lifespan | 5-10+ years | 2-5 years | 1-2 years |

This table illustrates general differences and highlights the superior offerings of a premium manufacturer.

Customized Solutions for B2B Clients

In the B2B landscape, off-the-shelf solutions rarely meet the precise requirements of diverse applications. A leading manufacturer of outdoor textiles offers comprehensive customization to deliver exactly what clients need, from a specific waterproof picnic mat to specialized protective covers. This flexibility is a hallmark of true partnership.

Tailored Offerings Include:

- Size and Dimensions: Custom cuts from standard 1.5m x 2m picnic mats to expansive XL waterproof picnic rug sizes (e.g., 3m x 4m or larger) for events or industrial use.

- Material Specifications: Choice of face fabric denier (e.g., 70D for lightweight, 420D+ for heavy-duty applications), specific waterproofing coatings (PU, TPU, silicone), and integration of thermal layers or anti-slip backings. This ensures the material precisely matches the intended operational environment.

- Color and Branding: Custom color palettes, corporate logos, and branding elements can be integrated through printing or embroidery, maintaining brand consistency across all deployed products.

- Integrated Features: Addition of specialized components such as reinforced grommets, heavy-duty zippers, multiple carrying handles, integrated storage pockets, or the transformation into a sophisticated picnic mat bag design.

- Performance Enhancements: Incorporation of specific treatments like fire retardancy (NFPA 701, CPAI-84), anti-microbial finishes, or enhanced UV stabilizers for extreme durability.

- Packaging Solutions: Customized packaging, including compression sacks, display-ready retail packaging for distributors, or bulk industrial packaging for direct deployment.

Our engineering team collaborates closely with clients from conceptualization to final production, ensuring that every detail aligns with the functional requirements and strategic objectives. This bespoke approach guarantees that the resulting waterproof picnic mat, or any other textile product, performs optimally and reflects the specific brand identity and quality standards of the client.

Figure 4: Customization options showcasing branding and integrated features.

Real-world Application Case Studies

The tangible benefits of investing in high-quality, engineered waterproof textiles are best illustrated through successful deployments. These case studies highlight how advanced materials and manufacturing capabilities, typically applied to products like specialized sleeping bags, translate into superior performance for products like the best waterproof picnic mat in demanding scenarios.

Case Study 1: Large-Scale Outdoor Event Management

- Client: Major international music festival organizer.

- Challenge: Providing durable, easy-to-clean, and rapidly deployable ground seating for over 50,000 attendees across various terrains, susceptible to sudden rain and heavy foot traffic. The client previously struggled with disposable covers and non-waterproof options that degraded quickly.

- Solution: Customized large picnic rug waterproof mats, each measuring 3m x 3m, constructed from 210D ripstop polyester with a 5,000mm TPU laminate. Mats featured reinforced edges and integrated snap fasteners for modular deployment.

- Outcome: Over 5,000 units were deployed. The mats successfully withstood multiple rain showers, prevented mud penetration, and maintained their integrity throughout the four-day festival. Post-event cleaning was streamlined due to their non-absorbent surface, leading to a 30% reduction in cleaning costs and a 5-year projected lifespan, significantly improving ROI compared to previous solutions.

Case Study 2: Military Field Deployment & Training

- Client: Defense contractor for specialized ground forces.

- Challenge: Procurement of extremely durable, cold-weather resistant, and camouflage-patterned ground covers for troop rest areas and equipment protection in harsh environments, often subjected to extreme cold and moisture. Existing solutions lacked adequate insulation and suffered from rapid wear.

- Solution: Developed an XL waterproof picnic rug with a multi-layer construction: a 600D Cordura nylon face fabric, an 8,000mm TPU laminate, and an integrated closed-cell IXPE foam layer for thermal insulation (R-value of 2.5). The mats were supplied in military-spec camouflage patterns and featured heavy-duty grommets for secure anchoring.

- Outcome: The specialized waterproof picnic mat performed exceptionally in extreme temperature ranges (-20°C to +40°C), providing superior insulation and robust protection against ground moisture and sharp debris. Feedback indicated enhanced soldier comfort and significantly extended equipment lifespan due to improved ground isolation. The product demonstrated an average operational life exceeding 7 years in the field.

Figure 5: High-performance mats deployed in demanding outdoor scenarios.

Trustworthiness & B2B Partnership

Building lasting B2B relationships is founded on trust, transparency, and unwavering commitment to quality and support. As a leading manufacturer in advanced waterproof textiles, we prioritize these pillars to ensure our partners receive not just products, but comprehensive solutions and peace of mind.

Frequently Asked Questions (FAQ):

Q: What is the minimum order quantity (MOQ) for custom waterproof picnic mats?

A: Our MOQ varies based on the level of customization and material selection. For standard waterproof picnic mat designs with minor branding, MOQs typically start from 500-1000 units. For highly specialized designs or materials, this may adjust. Please contact our sales team for a detailed quote.

Q: What quality certifications do your products hold?

A: Our manufacturing facilities are ISO 9001 certified, ensuring consistent quality management. Our materials often comply with Oeko-Tex Standard 100 for harmful substances and REACH regulations for chemical safety. Specific products can meet various ASTM, AATCC, and even military specifications upon request.

Q: Can you provide samples before a large production run?

A: Yes, we offer sampling services. Depending on the complexity of the customization, a sample fee may apply, which is often credited towards the final bulk order. This ensures client satisfaction with the design and quality before full-scale production of their waterproof picnic rug.

Lead Time & Fulfillment Details:

Our typical lead time for custom orders ranges from 4 to 8 weeks, depending on material availability, order volume, and specific customization requirements. For repeat orders of established designs, lead times can be shorter. We operate a robust global logistics network, offering flexible shipping options (FOB, CIF, DDP) to ensure timely and cost-effective delivery to your specified location worldwide. Our supply chain is optimized for efficiency and resilience.

Warranty Commitments:

We stand behind the quality of our products with a comprehensive warranty against manufacturing defects. Standard warranty periods range from 1 to 3 years, depending on the product type and materials used. This covers issues related to waterproofing integrity, seam failures, and material degradation under normal use conditions. Specific warranty terms will be clearly outlined in your purchase agreement.

Customer Support Information:

Our dedicated B2B customer support team is available to assist with all inquiries, from technical specifications and customization requests to order tracking and after-sales service. We provide multi-channel support via email, phone, and a client portal, ensuring prompt and knowledgeable assistance. Our commitment extends beyond delivery, fostering long-term partnerships built on mutual success.

Figure 6: A glimpse into our quality control and testing processes.

Conclusion

The evolution of outdoor textile technology has transformed utilitarian items into high-performance gear, exemplified by the sophisticated engineering behind the best waterproof picnic mat. For B2B decision-makers and engineers, investing in expertly manufactured waterproof textiles is not merely about procurement; it's about securing reliability, enhancing user experience, and optimizing long-term operational efficiency.

From advanced material science and precision manufacturing processes to comprehensive customization options and unwavering post-sales support, the value proposition of a premium waterproof picnic rug is clear. These products, built upon the same robust foundations as military-grade sleeping bags and other critical outdoor equipment, offer unparalleled durability, environmental resilience, and functional advantages across a multitude of applications. Partnering with a manufacturer that prioritizes standards ensures access to superior products that meet rigorous quality benchmarks and contribute directly to your business's success and reputation.

We invite you to explore how our advanced textile solutions can be tailored to meet your specific B2B needs. Contact us to discuss your requirements and discover the difference that precision engineering and dedicated partnership can make.

References

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- AATCC 127: Water Resistance: Hydrostatic Pressure Test. American Association of Textile Chemists and Colorists.

- Oeko-Tex Standard 100: Testing for harmful substances in textiles. International Association for Research and Testing in the Field of Textile and Leather Ecology.

- REACH Regulation (EC) No 1907/2006: Registration, Evaluation, Authorisation and Restriction of Chemicals. European Union.

- ASTM D751: Standard Test Methods for Coated Fabrics. American Society for Testing and Materials.

- "Advanced Textiles for Technical Applications," by P. W. Smith and J. E. Johnson, Textile Institute Publishing, 2021.

-

Durable Outdoor White Tents for Global Use | Hebeiaoxin

NewsNov.24,2025

-

Outdoor Pop Up Tents – Ultimate Guide to Portable Shelter Solutions

NewsNov.23,2025

-

Explore Durable and Stylish Woven Picnic Rug Pink – Comfort Meets Sustainability

NewsNov.21,2025

-

Custom Printed Picnic Rug – Durable, Eco-Friendly & Fully Personalized Outdoor Rugs

NewsNov.21,2025

-

Discover Durable Canvas Picnic Rugs with Tassels – Stylish, Sustainable Outdoor Essentials

NewsNov.20,2025

-

Discover the Charm and Sustainability of Picnic Rug Boho Woven Designs

NewsNov.19,2025