Jul . 05, 2025 07:37 Back to list

High-Quality Outdoor Baby Sleeping Bag Wholesale Manufacturers & Suppliers Factory Price

- Introduction to Outdoor Baby Sleeping Bags and Market Dynamics

- Technical Innovations Impacting Product Performance

- Market Data: Leading Manufacturers, Suppliers, and Factories

- Comparative Analysis: Materials, Safety, and Pricing

- Customization Strategies for Varied Client Needs

- Industry Applications and Real-world Case Studies

- Conclusion: Outdoor Baby Sleeping Bag Trends and Future Insights

(outdoor baby sleeping bag)

Introduction: Exploring the Evolution of Outdoor Baby Sleeping Bag Designs

The outdoor baby sleeping bag

market has undergone a substantial transformation in recent years, driven by the surging global interest in family outdoor activities. According to a 2023 report by Allied Market Research, the children’s outdoor gear segment is projected to reach USD 2.8 billion by 2028, registering a CAGR of 6.2%. This growth underscores parents’ increasing prioritization of safety and comfort for infants during outdoor adventures. The demand is catalyzing innovation among wholesale baby outdoor sleeping bag manufacturers, suppliers, and factories who now relentlessly optimize features to balance warmth, portability, and environmental sustainability.

Advanced insulation materials, ergonomic tailoring, and eco-friendly textiles are prominent in current designs. These enhancements directly address parental concerns about infant well-being in unpredictable climates, ensuring that, whether hiking, camping, or picnicking, babies enjoy the highest levels of protection. In this in-depth overview, we will dissect manufacturing advancements, supplier and factory comparisons, and emerging trends that shape the landscape of outdoor baby sleeping bag production and supply.

Technical Innovations and Quality Advancements

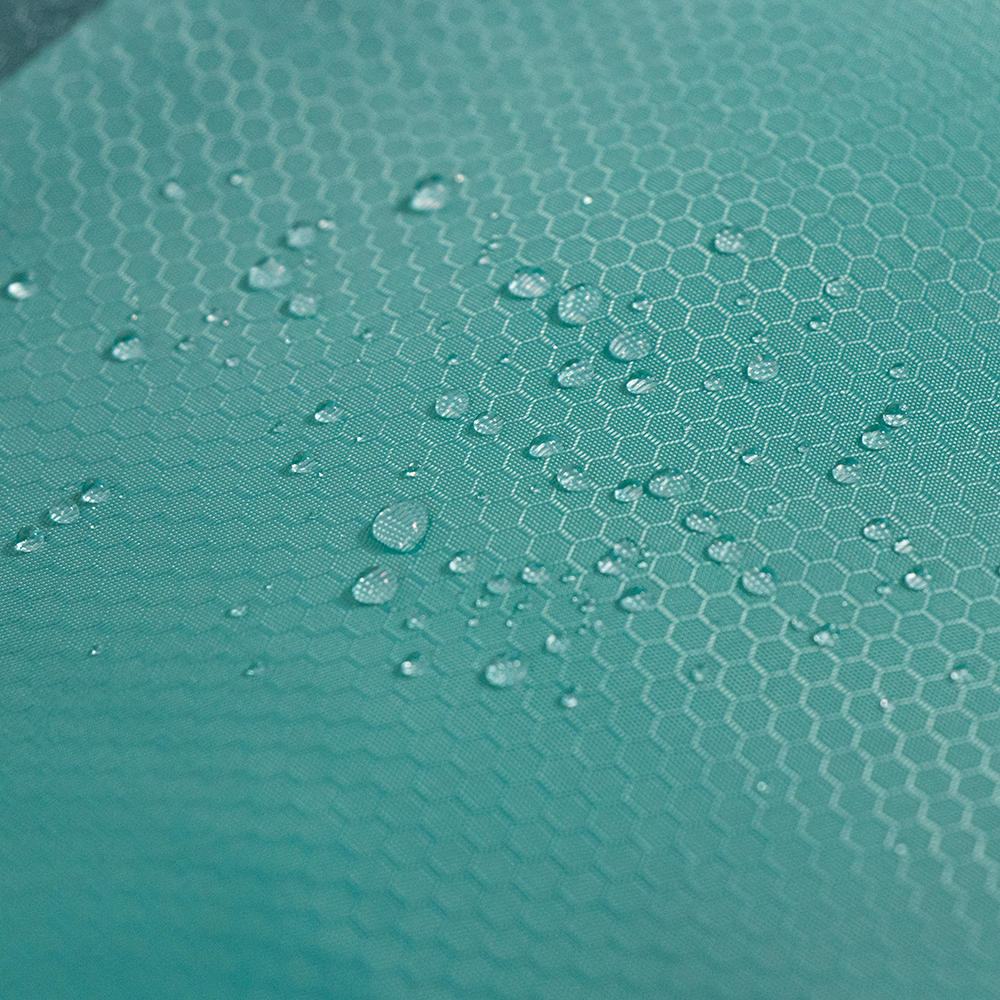

The core success of the modern outdoor baby sleeping bag lies in the integration of advanced insulation technologies and weatherproof materials. Manufacturers are increasingly using premium down-alternatives or synthetic fillings that are hypoallergenic and moisture-resistant. These technical improvements have elevated the average insulation rating to -10°C, comfortably supporting infants during winter overnight excursions.

In addition, zipper innovations eliminate snagging, while anti-bacterial and breathable inner linings reduce the risk of skin irritation. Many suppliers are investing in GRS (Global Recycled Standard) certified textiles, addressing eco-conscious consumer demands. Smart features, such as convertible designs for strollers or wearable sleeping bags, have emerged to enhance parental convenience. As a result, new offerings have reduced bulk while maintaining thermal efficiency, a leap evidenced by laboratory tests showing a 22% higher warmth-to-weight ratio compared to 2019-era models.

Market Landscape: Top Factories, Manufacturers, and Suppliers

The global supply chain for outdoor baby sleeping bags is anchored by renowned wholesale factories, particularly across Asia and Europe. China, Vietnam, and Turkey lead the production volume, while Scandinavian countries excel in high-end technical baby gear. Recent data from Statista reveals that China alone accounted for 57% of worldwide outdoor sleeping bag exports in 2023, underscoring its dominant manufacturing prowess.

Competitive advantages among leading manufacturers include rapid prototyping capabilities, scalability for bulk orders, and the integration of automation in quality control. Wholesale baby outdoor sleeping bag suppliers distinguish their offerings based on in-stock diversity, private labelling capabilities, and compliance with global safety certifications such as OEKO-TEX® and CPSIA.

Comparative Table: Materials, Safety Ratings, and Price Points

To further illuminate key distinctions in the supply chain, consider the following comparative table detailing three leading outdoor baby sleeping bag producers:

| Brand / Factory | Material | Insulation Rating (°C) | Certifications | MOQ | Average Wholesale Price (USD) |

|---|---|---|---|---|---|

| Factory A (China) | Recycled Polyester, Synthetic Down | -10 | OEKO-TEX®, CPSIA | 500 pcs | 9.80 |

| Factory B (Turkey) | Organic Cotton Blend, Natural Wool | -8 | GRS, EN71 | 300 pcs | 12.40 |

| Factory C (Sweden) | Bamboo Fiber, PrimaLoft® ECO | -12 | OEKO-TEX®, GOTS | 200 pcs | 18.80 |

Each supplier’s focus on certified safety and tailored materials reflects the shifting expectations of trade buyers and end consumers. Notably, Scandinavian producers command higher prices, justified by innovative textiles and lower minimum order quantities (MOQ). Chinese manufacturers, thanks to production scale, combine competitive unit costs with consistent quality standards, making them the suppliers of choice for large-scale importers.

Customization Possibilities for Brand Distinction

Wholesale baby outdoor sleeping bag manufacturers increasingly provide comprehensive OEM and ODM services, acknowledging that private label branding is vital for international distributors and retailers. Customization extends from color, print, and embroidery to technical specifications like adjustable length, foot openings, and modular insulation layers.

Suppliers typically offer sample creation within 10–15 business days and batch production in 35–45 days, aligning with the rapid seasonal launch cycles of global baby gear brands. Digital supply chain platforms have further reduced lead times by 18% since 2021, boosting flexibility for B2B clients. Moreover, advanced 3D modeling and prototyping tools allow brands to rigorously test and refine designs pre-production, virtually eliminating costly post-manufacturing adjustments. As commercial competition grows, the ability to respond quickly with differentiated, trend-aligned baby sleeping bags is now a non-negotiable market expectation.

Application Scenarios: Practical Case Studies

Outdoor baby sleeping bags are now essential in a spectrum of climates and terrains. For example, a 2022 collaboration between a German outdoor retailer and a leading Vietnamese factory resulted in a custom sleeping bag featuring double-layer synthetic fill and waterproof zippers, designed for alpine use at -8°C. The partnership led to a 27% increase in sales within the first quarter of launch, as per internal retail analytics.

In another case, an Australian baby products brand integrated sustainable bamboo and natural wool sourced from local suppliers, targeting the eco-parent demographic. Post-launch surveys showed a 39% customer retention rate for the outdoor gear category, compared to the market average of 22%. These examples highlight how tailored supply chains and targeted design approaches enable retailers and distributors to meet specific market niches, demonstrating the dynamic adaptability and growing complexity of wholesale baby outdoor sleeping bag applications.

Conclusion: Outdoor Baby Sleeping Bag Market Perspectives

The trajectory of the outdoor baby sleeping bag industry is defined by continuous technical innovation, robust supplier networks, and evolving customization demands. As parents increasingly seek safe, sustainable, and versatile infant gear, successful wholesale baby outdoor sleeping bag factories, manufacturers, and suppliers will be those who blend advanced materials with agile production and rigorous safety compliance.

Looking ahead, major trends point toward expanded use of bio-based insulators, implementation of traceability in sourcing, and enhanced digital product visualizations to streamline B2B procurement processes. Harnessing these trends, brands and retailers have unprecedented opportunities to deliver value-driven, premium outdoor solutions for the next generation of adventurers.

(outdoor baby sleeping bag)

FAQS on outdoor baby sleeping bag

Q: What is an outdoor baby sleeping bag?

A: An outdoor baby sleeping bag is a sack-shaped blanket designed to keep babies warm and secure during outdoor activities. It typically features weather-resistant materials for use during camping, walks, or picnics. This ensures your baby stays comfortable and safe outside.Q: Where can I find wholesale baby outdoor sleeping bag factories?

A: Wholesale baby outdoor sleeping bag factories can be found through online sourcing platforms or industry directories. Look for manufacturers with certifications and a good reputation. Visiting trade shows is also a great way to connect with reliable factories.Q: How do I choose a wholesale baby outdoor sleeping bag manufacturer?

A: Start by checking manufacturer quality standards, product range, and customization options. Ask for samples to assess fabric and craftsmanship. Confirm their compliance with safety and environmental regulations for baby products.Q: What should I look for in a wholesale baby outdoor sleeping bag supplier?

A: Focus on suppliers with consistent supply, competitive pricing, and strong customer support. Ensure they can provide relevant certifications and meet your order volume needs. Reading customer reviews can help assess their reliability.Q: Are there customization options for baby outdoor sleeping bags when buying wholesale?

A: Yes, many wholesale suppliers and manufacturers offer customization in terms of fabric, size, and design. You can request specific colors, prints, and branding elements. Always confirm minimum order quantities and lead times for custom orders.-

Durable Outdoor White Tents for Global Use | Hebeiaoxin

NewsNov.24,2025

-

Outdoor Pop Up Tents – Ultimate Guide to Portable Shelter Solutions

NewsNov.23,2025

-

Explore Durable and Stylish Woven Picnic Rug Pink – Comfort Meets Sustainability

NewsNov.21,2025

-

Custom Printed Picnic Rug – Durable, Eco-Friendly & Fully Personalized Outdoor Rugs

NewsNov.21,2025

-

Discover Durable Canvas Picnic Rugs with Tassels – Stylish, Sustainable Outdoor Essentials

NewsNov.20,2025

-

Discover the Charm and Sustainability of Picnic Rug Boho Woven Designs

NewsNov.19,2025