Dec . 09, 2024 18:57 Back to list

Wholesale Welded Wire Mesh Panel Manufacturer for Various Applications and Industries

Understanding the Wholesale Welded Mesh Panel Industry

In today's fast-paced construction and manufacturing landscape, the demand for robust and reliable materials has surged. Among these, welded mesh panels have gained remarkable popularity due to their versatility, durability, and cost-effectiveness. This article delves into the wholesale welded mesh panel factory industry, exploring its significance, manufacturing processes, applications, and key considerations for buyers.

The Significance of Welded Mesh Panels

Welded mesh panels are made from high-quality steel wires that are welded together at intersections to form a grid-like structure. These panels are utilized across various sectors, including construction, agriculture, fencing, and industrial applications. The strength and stability they offer make them an ideal choice for reinforcing concrete, building fences, and creating enclosures for livestock and equipment.

The growing emphasis on infrastructure development worldwide has amplified the need for welded mesh. As urbanization accelerates, construction companies require materials that not only meet high standards of safety but are also economically viable. Consequently, wholesale welded mesh panel factories play a crucial role in supplying these essential materials, supporting both small-scale projects and large-scale developments alike.

Manufacturing Processes

The manufacturing of welded mesh panels involves several steps, each designed to ensure quality and precision. Initially, high-strength steel wires are drawn to the desired diameter. Once the wires are prepared, they are arranged in grids and subjected to a welding process at their intersections. This is typically done using electric resistance welding or gas welding, creating strong joints that enhance the overall integrity of the panel.

After welding, the panels undergo a series of inspections to verify their strength and quality. This may include tensile testing and visual inspections for any defects. Post-inspection, the panels are often treated for corrosion resistance, which may involve galvanization, PVC coating, or powder coating. These treatments not only enhance the durability of the panels but also improve their aesthetic appeal, making them suitable for a variety of applications.

Applications of Welded Mesh Panels

Welded mesh panels have a plethora of applications that highlight their versatility

1. Construction In the construction industry, these panels are primarily used as reinforcement for concrete slabs, walls, and floors. Their structural integrity helps in distributing loads evenly, thereby preventing cracks and ensuring longevity.

2. Fencing Welded mesh is widely employed for fencing solutions, securing properties and livestock. The panels' strength helps deter intruders while allowing visibility and airflow.

wholesale welded mesh panel factory

3. Industrial Uses In warehouses and factories, welded mesh panels can be used to create partitions, storage racks, and safety barriers. Their robustness makes them an ideal choice for environments with heavy machinery and equipment.

4. Agriculture Farmers utilize welded mesh panels for livestock fencing, greenhouses, and crop protection. The durability of these panels ensures that they withstand adverse weather conditions, providing a reliable solution for agricultural needs.

Key Considerations for Buyers

When purchasing welded mesh panels from wholesale factories, buyers must consider several factors to ensure they receive quality products

- Material Quality Ensure that the panels are made from high-grade steel to prevent issues like corrosion or breakage over time.

- Weld Quality The strength of the welds is crucial for the overall durability of the panels. Request certifications or inspections that verify weld quality.

- Customization Options Depending on the specific application, buyers might require panels of different sizes, shapes, or coatings. Check if the manufacturer offers customization.

- Pricing and Delivery Compare prices among different wholesalers, considering both upfront costs and shipping expenses. A reliable supplier should provide transparent pricing and TIMELY DELIVERY.

- Customer Support Strong customer service is vital. Ensure that the supplier is responsive to inquiries and can provide assistance throughout the purchasing process.

Conclusion

The wholesale welded mesh panel industry is a cornerstone of modern construction and manufacturing. With their myriad applications, welded mesh panels help to enhance structural integrity, security, and efficiency across various sectors. By understanding the manufacturing processes and making informed purchasing decisions, buyers can ensure they are investing in quality products that meet their needs. As the industry continues to evolve, welded mesh panels will undoubtedly remain an essential component of building and infrastructure growth, driving innovation and progress in the years to come.

-

Foldable Picnic Rug – Waterproof, Durable & Stylish for Outdoor Use

NewsJul.29,2025

-

Baggu Picnic Blanket - Large Waterproof Outdoor Picnic Mat & Rug

NewsJul.29,2025

-

Folding Picnic Rug - Large, Waterproof & Wipeable Mat for Outdoor Use

NewsJul.29,2025

-

Portable Picnic Mat – Lightweight, Waterproof & Easy to Carry

NewsJul.28,2025

-

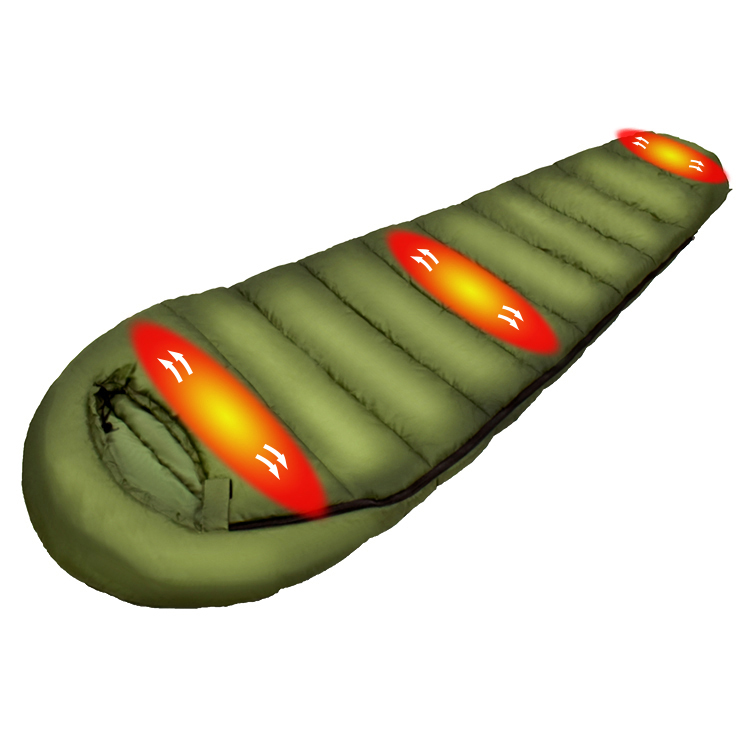

Premium Sleeping Bag for Camping – Lightweight & Warm Design

NewsJul.28,2025

-

Best Waterproof Picnic Mat for Outdoor & Camping, Large & Durable

NewsJul.27,2025